ENERGY

From Prof. Elston's Wiki

Contents |

Steam System

What is the Steam System?

The current New York City steam system is the result of over 120 years of expansion of the original system. The original New York steam system was opened in 1882 by the New York Steam Company. This initial system was made of 3 miles of main that serviced 62 customers.[3] By the time Con Edison purchased the system in 1936, the system had expanded to 65 miles of main, included 6 generating units, and served 2,500 buildings.[3] Currently, the system is made up of over 100 miles of main and service pipes and serves more than 1,800 customers, making New York City's steam system the largest district steam system in the United States.[2]

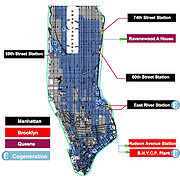

Steam systems are most efficient where population is dense. In Manhattan, people are concentrated where buildings are tallest - that is, Midtown and lower Manhattan. For this reason, the steam system stretches from the tip of Manhattan at the Battery to 96th Street on the West Side and 89th Street on the East Side.

Con Edison’s steam system is supplied by seven steam plants, five of which - 59th Street, 74th Street, 60th Street, Ravenswood, and Hudson Avenue - are steam only. The remaining two - East River Station and Brooklyn Navy Yard Cogeneration Partners (B.N.Y.C.P) - are cogeneration, meaning that they produce both steam and electricity. Con Edison owns all of the plants that supply steam to the steam system except the B.N.Y.C.P plant.

Steam Generation

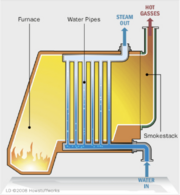

Boilers located at steam stations convert water to steam. Water from the New York City Drinking Water supply is tunneled into the pipes inside the boilers. Then, fuel is burnt inside of the boilers. In Con Edison’s system, only natural gas or fuel oil is used. The burning of the fuel raises the temperature inside the boiler to 1,000◦ Fahrenheit, thereby converting the water to steam. This process converts 1 gallon of water into 8 lbs of steam. On average, the system's boilers convert 125,000 gallons of water into 1 million lbs of steam per hour of operation.[5] After water has been turned into steam, it is piped into the steam distribution system at a temperature of 350◦ Fahrenheit.[5]

Steam Distribution System

The Con Edison Steam Distribution System is a network of underground pipes and mains that deliver steam to customers from the steam plants. Larger pipes that extend directly from the steam plants are called mains. Services pipes are smaller pipes that branch off from the main and connect to the customer. Main diameters vary from 8 to 36 inches and service pipes diameters range from 2 to 16 inches. The mains and service pipes are of varying sizes in order to accommodate varying pressures. Generating plants that supply steam to far away customers pump steam into the system through higher-pressure steam mains - at a pressure of 400 pounds per square inch (psig) - that then transitions to lower-pressure distribution mains. Other generating plants that are located closer to customers usually provide steam directly to the distribution system at pressures below 200 psig.[4]

Steam System’s Customers

By Con Edison’s estimation, the steam system serves 1,800 customers in 100,000 commercial and residential building with steam for heating, air conditioning, hot water, sterilization, cooking and humidification. Over half of Con Edison's customers are businesses, with 54% of customers in the commercial sector, 7% hospitals, 6% hotels, and 2% museums. Residential buildings account for 19% of all customers. Major steam customers and consumers include the United Nations, Empire State Building, New York University Medical Center, Lincoln Center, Metropolitan Museum of Art, and Grand Central Terminal. Con Edison also boasts many other notable NYC buildings as customers including New York Times Headquarters, Gramercy Park Hotel and Time Warner Center.

Benefits of the Steam System

There are significant environmental, financial and consumer benefits of a centralized steam system as opposed to on-site boilers. With the global temperature and greenhouse gas levels rising, the environmental benefits of the steam system become increasingly important. First, central generating stations are regulated by the government, allowing for constant monitoring and a greater guarantee towards adherence to environmental standards. If each steam customer had his or her own boilers on the site of the building, it would be impossible to regulate the system, and to guarantee that all boilers were running efficiently and cleanly. Additionally, with the current Con Edison steam system, most of the fuel used is natural gas, a relatively clean burning fossil fuel. At the moment, Con Edison proposes the use of 90% natural gas and 10% number 6 oil. With on-site boilers, there would be no way to guarantee that individual boilers use clean fuels, however, a centralized system is subject to rigorous and frequent inspections. A centralized fuel system also takes trucks off the roads, which reduces fuel use. With individual boilers, fuel trucks would need to deliver to each individual site, as opposed to the fewer centralized generating stations. Using steam to cool saves 350MW of electricity as well. In addition, the steam system has emission benefits. The steam system produces one third less CO2 per pound delivered as compared to on-site boilers, which burn 10% more oil than the steam system. Additionally, half of the steam in New York City generated today comes from cogeneration, which offsets about 1.5 million tons of CO2 annually. This reduction in CO2 is due to the fact that cogeneration uses a quarter less fuel than separate steam and electricity generation. The use of steam cooling instead of electric cooling also provides emission benefits because steam cooling produces three times less NOx per ton of cooling during peak hours.[6, 8, 7]

The most significant aspects of the steam system are those benefits realized by the consumer. For one thing, central generating stations allow for centralized maintenance. This increases system reliability and shields individual landlords or on-site-owners from the cost of maintaining an on-site boiler. Additionally, it allows for ease of mind for individuals. For example, if personal boilers were to fail, it is likely that building owners would be without steam services for some time. Boiler failure could more easily result on an on-site boiler where less time and money is put into maintaining the boiler when compared to a steam company where their largest concern is, obviously, steam production. Thus, it is more likely that the centralized boilers are inspected and maintained regularly. Additionally, the presence of centralized plants eliminates the need for on-site boilers and frees up valuable space. For the average 600,000 square foot building, one would require 1,500 square feet of boiler space. On a purely aesthetic level, the underground centralized steam system allows for only centralized plumage at the generation stations. Individual boilers would require chimneys on each producers building, which would cause street level air to be polluted and the skyline to be burdened by hundreds of plumes of smoke.Aside from this, there are purely financial reasons for supporting a centralized steam system. Put simply, on-site boilers are expensive. In order to convert the 1,800 steam customers to on-site gas boilers would cost a collective $1.4 billion. For buildings greater than 20 stories, on-site generation would be exceedingly expensive, as one would need to generate enough steam to provide for the upper floors. If the steam system did not exist, the city would need to lay new natural gas pipes, as well as accompanying stations, plus reinforcements for existing infrastructure and new meters. All of this would be paid for in increased energy bills, leading to a financial loss for the consumer.

Steam for Cooling

Steam cooling is the process of using steam to cool an environment. Though it is counter-intuitive to think that hot gas can cool, steam cools in a process similar to how a refrigerator works. Independent of the implementation, all steam-cooling methods follow the physical property, pV=nRT, where pressure and temperature are directly proportional. The heat from steam helps increases the pressure in a compressor. The gas in the compressor is allowed to circulate and heat is dissipated. When there is a loss in heat, this condenses the gas in the compressor to liquid that decreases pressure. A decrease in pressure results in a decrease in temperature, and thus a cooler environment is created. The advantage of steam cooling is that there is less demand on the energy grid. By cooling with steam, consumers do not need to depend on conventional electric air conditioners, but can take advantage of the existing network.

Cogeneration

What is Cogeneration?

The basic mechanism for generating an electrical current requires the rotation of wire loop (an armature) through a magnetic field. The rotation creates an electron motive force, which in a closed circuit (our electrical systems) can be used to do work, such as power our subways, elevators, light bulbs and blenders to name a few examples. In order to generate a sufficient current, the speed at which the wire coil rotates and the amount of wire must be great enough. In order to supply the energy for this process, we burn fuels such as oil and natural gas, or we turn to alternative sources of energy, some of which are renewable. In early days of large-scale electricity generation, the machine that powered the rotation of the coil was a steam engine.

For a long time most of these steam engines were powered by burning coal (we still get close to 50% of the energy in the country from coal power today), which is not only dirty but also destructive to mine and inefficient from a thermodynamics standpoint (most of the energy in the coal was given off as waste). Today we use turbines that are more efficient in order to convert the heat energy from combustion into the mechanical rotation of an armature.Electricity

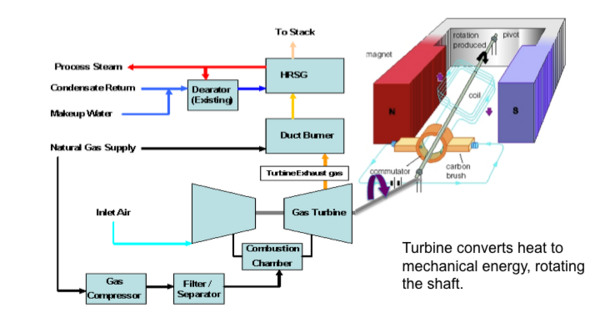

Chemical energy in a fuel is released by combustion and is used to heat a gas. This gas is then pressurized and shot at the blades of the turbine, causing rotation of the turbine and the generation of a current. No matter how efficient we make these turbine systems, some energy will always be given off as waste heat. Classical generation techniques using one very efficient gas turbine can reach about 40% efficiency, leaving plenty of room for improvement.

Cogeneration and HRSG

Along with generating electricity, Con Edison also produces and transports steam. The steam is produced at different boiler sites and is sent through the steam system. The processes of electricity and steam generation classically occur independently of one another, but the appearance of a relatively new practice called CHP, or combined heat and power, might change that. Combined heat and power, otherwise known as cogeneration, is a method to capture the waste heat given off by electricity generation and use it to generate steam. The goal is to be as fuel efficient as possible while generating two important resources,steam and electricity. This fuel efficiency equates to less air pollutants such as CO2 , NOx, and SOx, as well as lowering the cost of resource production. Before cogeneration, comes combined cycle generation. Combined cycle generation is one step that makes use of some of the excess heat from electricity generation, but it does not produce a heat resource as well as power. Combined cycle power plants use an HRSG (Heat Recovery Steam Generator) to produce steam from waste heat given off by the first cycle. This steam is then pressurized and applied to a second turbine (this one a steam turbine, while the first was a gas turbine) to generate more electricity. This process can reach thermo efficiency values reaching above 60%. Cogeneration differs from combined cycle generators because it takes the process a step further. Even after the steam turbine generator is powered by the steam from the HRSG, there is more excess heat and steam. Cogeneration allows for the capture of this excess steam for use at a nearby location, which in our case is the steam system.

Harmful Effects of Pollution

Carbon Dioxide

Evidence shows that the burning of fossil fuels, such as oil, petroleum, natural gas, and coal, results in the harmful emissions of carbon dioxide, carbon monoxide, nitrous oxide, sulfur dioxide, lead, and particulate matter, which each carry their own repercussions. There are ways to offset the harmful effects of burning fossil fuels, but action must be taken now, as the predictions for the near future for business as usual fossil fuel use are dire.

The release of carbon dioxide from the burning of fossil fuels is of huge concern in regards to climate change. Since the Industrial Revolution, there has been a 35% increase in the amount of CO2 in the Earths atmosphere. Until recently, CO2 was not thought of as potentially harmful, but with the discovery of the greenhouse effect, it has become obvious that the excess of CO2 in our atmosphere is one of the most harmful pollutants. In 2005, humans were releasing 7.2 global tons of CO2 annually. CO2 and other greenhouse gases block heat that is radiated from the Earth, as opposed to letting it escape into space. While this is good in principle, and operated well while CO2 levels were natural, the increase of greenhouse gases in the atmosphere since the Industrial Revolution has resulted in the retention of too much heat. As a result, the Earth is getting warmer. Since 1900, there has been a .8◦C increase in global temperature. This trend of warming has had and will continue to have drastic effects. For one, the increase in heat causes increased evaporation of lakes and ponds. As a result of this, many bodies of water, such as the Finger Lakes, are decreasing in size. Increased evaporation and temperatures also negatively affect biodiversity. Many species will be unable to adapt to the changing climate and ecosystems. Scientists estimate that up to 1/3 of the current species on Earth will be extinct or in danger by 2050. These losses of species might also impact food supply. Another negative effect of evaporation is that an increased amount of warmer water in the atmosphere would lend greater power to tropical storms, thereby increasing the number of high level hurricanes, storms, and floods that would occur. The occurrence of a 100 year flood in New York City has been estimated to decrease to as often as once every 19 years by 2050.

Another particular danger of global warming is the melting of glaciers and ice sheets in the Arctic. In the past 30 years, 1.5 million km2 of sea ice has been lost, due to a 1.3◦ C increase in Arctic temperatures. This melting ice contributes to a rise in sea level; a 15-20 cm increase in sea level has been recorded in the past century. The rapid melting of the ice caps is increasingly dangerous because it is self perpetuating. Ice is reflective, and as more of it disappears, dark, heat absorbing water is revealed. Thus, as the area of the ice diminishes, more heat is absorbed by the water, causing the ice to melt faster. The potential loss of the Arctic circle is a direct threat to those that live there - some 4 million people and various species. Additionally, 40 million people rely on glacial runoff for their water supply. Where these people will get their water when the glaciers disappear is a huge concern, one that has no solution at the moment. [10]

Nitrogen Oxide

Nitrogen Oxides are a component of acid precipitation, which occurs when chemicals emitted in smoke mix with the water in the atmosphere, making it more acidic. Acid precipitation is harmful when it falls back to Earth because it can cause severe damage to plant life and can lower the pH of bodies of water, which often kills many of the species living in them. Excesses of nitrogen in the water - often as a result of acid rain - can cause eutrophication, in which aquatic plant life, such as algae, consume the nitrogen and proliferate, thereby depleting oxygen levels in the water consequently preventing other species from living in the water.

Nitrogen oxides are also a component of ground level ozone, a pollutant that forms when other pollutants (nitrogen oxides, sulfur oxides, volatile organic compounds, etc) react in heat, to create smog, haze, and health problems such as respiratory infections, lung inflammation, and eye irritation. It also damages crops and forests. [9]

Sulfur Oxides

Similar to nitrogen oxides,sulfur oxides are a component of acid rain, haze, and ground level ozone. They also contribute to particle pollution, which are solid particles in the air. These are dangerous because living beings are not meant to breathe solids, and these particles, which are often incredibly small, can bore into the lungs and cause inflammatory responses and respiratory infections.[9]

Application to 59th Street

Current Operations

Con Edison’s 59th Street Steam plant was designed by Stanford White in 1902 for the purpose of electricity generation.[1] The building is characterized by its immense size - it occupies an entire city block. Also, the building features an ornate facade, large picturesque windows, and, originally, six smokestacks that were designed to imitate the steam ships that were once stationed next to the plant on the Hudson River. Since Con Edison converted the plant into a steam only facility in the 1950s, the exterior of the building has suffered - it is in desperate need of cleaning, the original smokestacks have been removed in favor of one, tall smokestack, windows have been boarded up, and new entryways have been cut into the building without attempts to maintain the aesthetics of the original design and structure.

Since the conversion, the 59th street plant has been rendered largely inefficient. It has the capacity to produce 1,331 mlb/hr of steam, which is sufficient to meet the demands of the system, but the building itself is mostly empty. The facility uses 58% No.6 oil, which is relatively unrefined and, therefore, not the cleanest fuel that could be used. Ideally, the station would use entirely natural gas, which would be a much cleaner alternative source that is capable of maintaining the plant’s capacity.

With the question of efficiency at hand, and with the prior discussion of cogeneration, maintaining 59th Street as a steam only plant seems inherently inefficient. To improve upon this, and to protect Stanford Whites landmark of architecture, we propose replacing the 59th Street plant with a cogeneration plant that matches the steam output while providing an additional electrical output.

Methodology

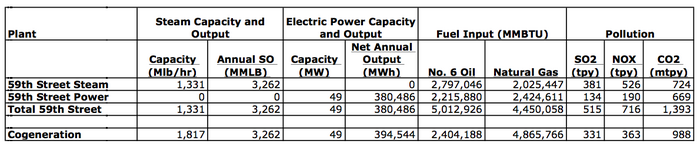

All values for Carbon Dioxide emissions were calculated using a rate converting MMBTU of fuel input to tons per year of CO2 emissions. Different rates were used for Natural Gas and No. 6 oil. The conversion rates come from the EIAs voluntary reporting of greenhouse gases program. Information on 59th street steam station excluding CO2 emissions were found in “Worley Parsons Long Term Con Edison Steam Production Options Study Phase 1; Final Report”.

Values for electricity generation corresponding to 59th street station were obtained by taking the average of four power plants’ net annual electricity generation, fuel input and capacity. The data on these four plants was found using the EPAs “eGRID2007 Version1-1” database. The plants were chosen based on how close their annual electricity output was to the cogeneration option. The SO2 and NOx emissions for 59th streets power equivalents were generated using average emissions per MWh in the NYC/Westchester region. This rate was included in the “EPAs eGRID2006 Version2-1 Summary Tables” document.

The values for the cogeneration option are based on the cogeneration option 1 outlined by the “Worley Parsons” report in their consideration for replacing the current 59th street operation with cogeneration. This is similar to the cogneration option 3 considered in the same report. The values presented by “Worley Parsons” were scaled up proportionally in order match 59th streets steam output.[11]

Analysis of Current Options

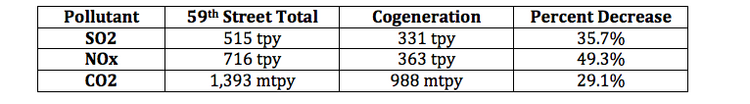

The row in Figure 1 showing power generation and emissions for 59th street allows 59th street to match cogeneration in resource production by adding a proxy electricity generation statistic to the current steam only operation. The independent generation of steam and electricity represented by the 59th street categories show significant inefficiency when compared to the values of the hypothetical cogeneration facility. The cogeneration option is an improvement over 59th street on two main fronts: fuel efficiency and reducing environmental pollution. Cogeneration uses an overall of 2,193,030 MMBTu less annual input of heat to produce the same steam and power output. Less annual fuel consumption equates to lower fuel costs, although the MHC Energy Group 09 did not evaluate the financial aspects of this proposal and an additional study would be required to ascertain them.

Reduced fuel consumption also contributes to lowering the overall output of pollutants. The environmental dangers and health risks of SO2 , NOx and CO2 pollutants have already been outlined previously in this report. The cogeneration option shows a substantial decrease in each of these pollutants.

Concluding Thoughts

After considering the condition of the steam station at 59th street, the potential for electricity output and of the environmental benefits of reducing air pollution, the MHC Energy Group 09 suggests constructing a cogeneration facility to replace the current operation at 59th street. Additional studies would be required to assess the financial and engineering feasibility of this switch.

PowerPoint and Video Presentations

References

[1] The New York Subway: Its Construction And Equipment, 1904. http://www.nycsubway.org/articles/irtbook ch3.html.

[2] Steam System, November 2009. http://www.coned.com/newsroom/energysystems steam.asp.

[3] Robert Agnello, David Bomke, Timothy Daniels, Michael Delaney, Victoria Galsterer, George Gerritsen, Catherine Luthin, Marco Padula, Michael Santarcangelo, and Lee Smith. Steam business development plan for the Consolidated Edison steam system development task force with the assistance of ccn man- agement counsel and thornton energy associates. Technical report, Steam Business, 2007.

[4] Vincent Badali. Steam operation: An overview. Technical report, Consolidated Edison Company of New York, Inc., 2007.

[5] Carl Bevelhymer. Steam. Gotham Gazette, November 2003. http://www.gothamgazette.com/article/issueoftheweek/20031110/200/674.

[6] Inc. Consolidated Edison Company of New York. Benefits of the steam system. Technical report, Consolidated Edison Company of New York, Inc., April 2009.

[7] Inc. Consolidated Edison Company of New York. Supplement to the 2007 steam resource plan. Power- point, December 2009.

[8] Inc. Consolidated Edison Company of New York. Technical conference steam resource plan Hudson Avenue steam station. Technical report, Consolidated Edison Company of New York, Inc., March 2009.

[9] EPA. The plain english guide to the clean air act. Technical report, EPA, Office of Air Quality Planning and Standards, Research Triangle Park, NC, April 2007.

[10] Susan Joy Hassol. Impacts of a warming arctic. Technical report, Arctic Climate Impact Assessment (ACIA), 40 West 20th Street, New York, NY 10011-4211, USA, 2004.

[11] Worley Parsons. Long term Con Edison steam production options study. Technical report, Worley Parsons, October 2006.